A Ready-to-assemble Cleanroom Kit Supports Medicated Tampon Start-up

In their search for a cleanroom solution, CBD-infused tampon manufacturer, Daye, discovered C2C’s ready-to-ship cleanroom range. The 6x3m modular hardwall cleanroom achieves ISO 14644-1 class 7 and was the right size to accommodate Daye’s production machinery.

Key facts

Ready-to-ship cleanroom

Available from stock

ISO Class 7

Hardwall construction

2 zones

Change area and production area

Cleanroom LED lighting

Providing process-compliant lux levels

About Daye

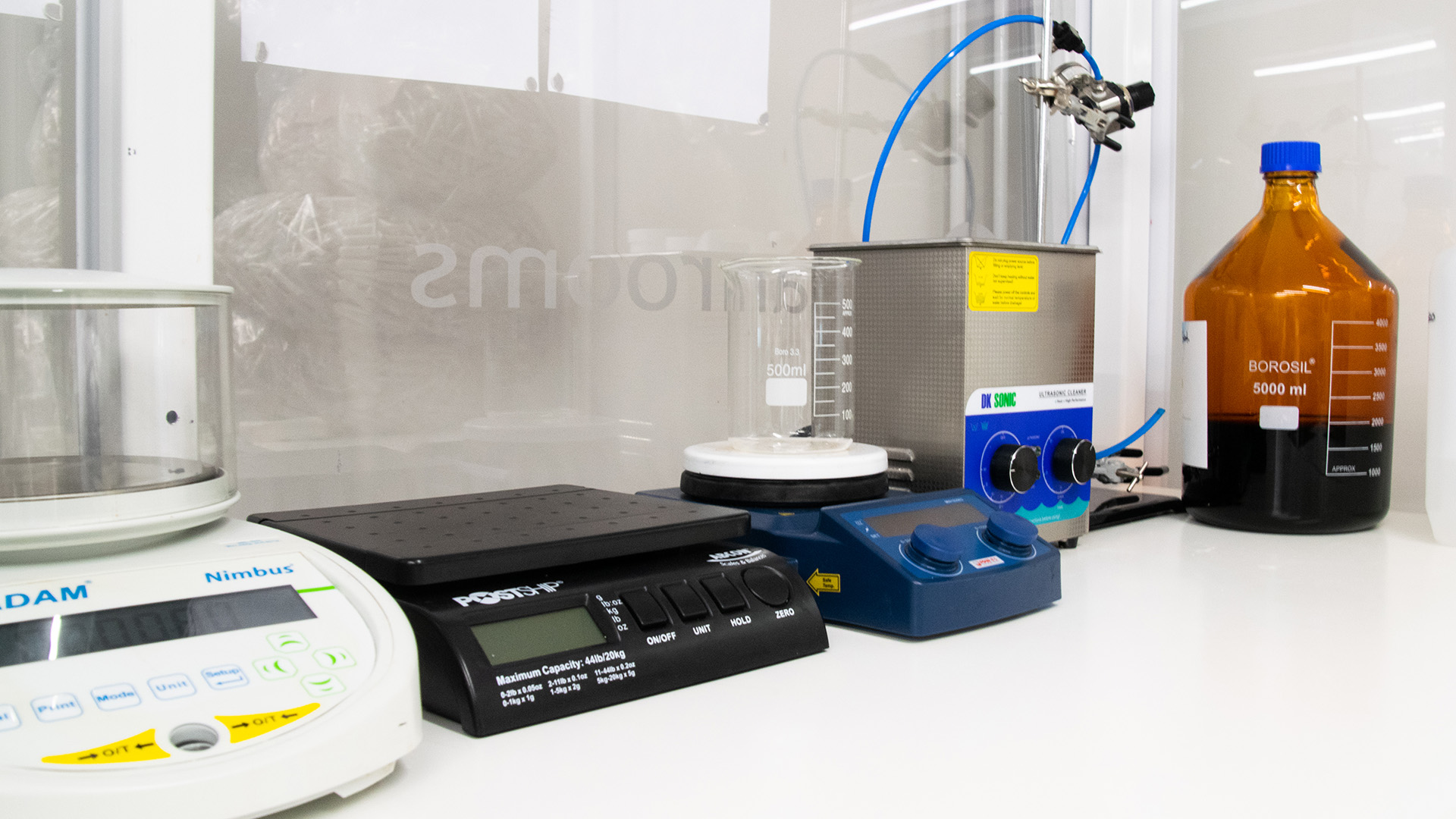

Daye exist to raise the standards of women’s health by creating effective products and services. Daye produce a highly absorbent tampon, produced in a cleanroom then sterilised with gamma rays to significantly reduce the risk of Toxic Shock Syndrome (TSS) compared with other tampon brands. They also produce a tampon that is infused with a cannabidiol formulation, which has been clinically validated to relieve period cramps.

Currently Daye have 6,000 subscribers in the UK, Holland and Ireland which have been acquired since March 2020.

The requirement

Even though tampons are not classified as medical devices in Europe, Daye believe in adopting the strictest possible guidelines and protection methods to produce the safest possible product. This drove them in search for a cleanroom that would be able to house their production machinery and deliver high volumes of clean air, within a start-up’s budget.

The solution

In their search for a cleanroom solution, Daye discovered C2C’s ready-to-assemble cleanroom range. The 6x3m hardwall model achieves ISO 14644-1 class 7 and was the right size to accommodate Daye’s production machinery. It was also available from stock and included a transfer area for gowning and materials transfer.

- Complete cleanroom, including HEPA filtration, LED lighting, change area

- 5m x 3m Production Area

- 1m x 3m Change Area

Cleanroom production was a completely new process for Daye, so C2C also provided cleanroom training on protocols such as gowning and cleaning.

It was great to find an off-the-shelf cleanroom that fit our machinery and we could put into production straight away.

With C2C, we identified a partner who could help us understand our options and share our commitment to implementing the highest possible standards.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE