Cleanroom and Warm Room Rebuild for E-liquid Manufacturer

Connect 2 Cleanrooms (C2C), worked closely with Blend & Bottle to create an ISO 14644-1:2015 classified cleanroom facility which could support its process and be future-proofed against potential changes to TPD legislation.

Key facts

396m² cleanroom for e-liquid production

Monobloc and hardwall construction

MAC 10® LEDC FFUs provide advanced energy efficiency for the supply air

Warm room features heating up to 50°C ± 2°C

What did the client need?

When a serious blaze halted production for Blend & Bottle, the OEM e-liquid and CBD oil producer turned disaster to fortune by seizing the opportunity to upgrade its production facility in Stockport, Cheshire. Connect 2 Cleanrooms (C2C), worked closely with Blend & Bottle to create an ISO 14644-1:2015 classified cleanroom facility which could support its process and be future-proofed against potential changes to TPD legislation.

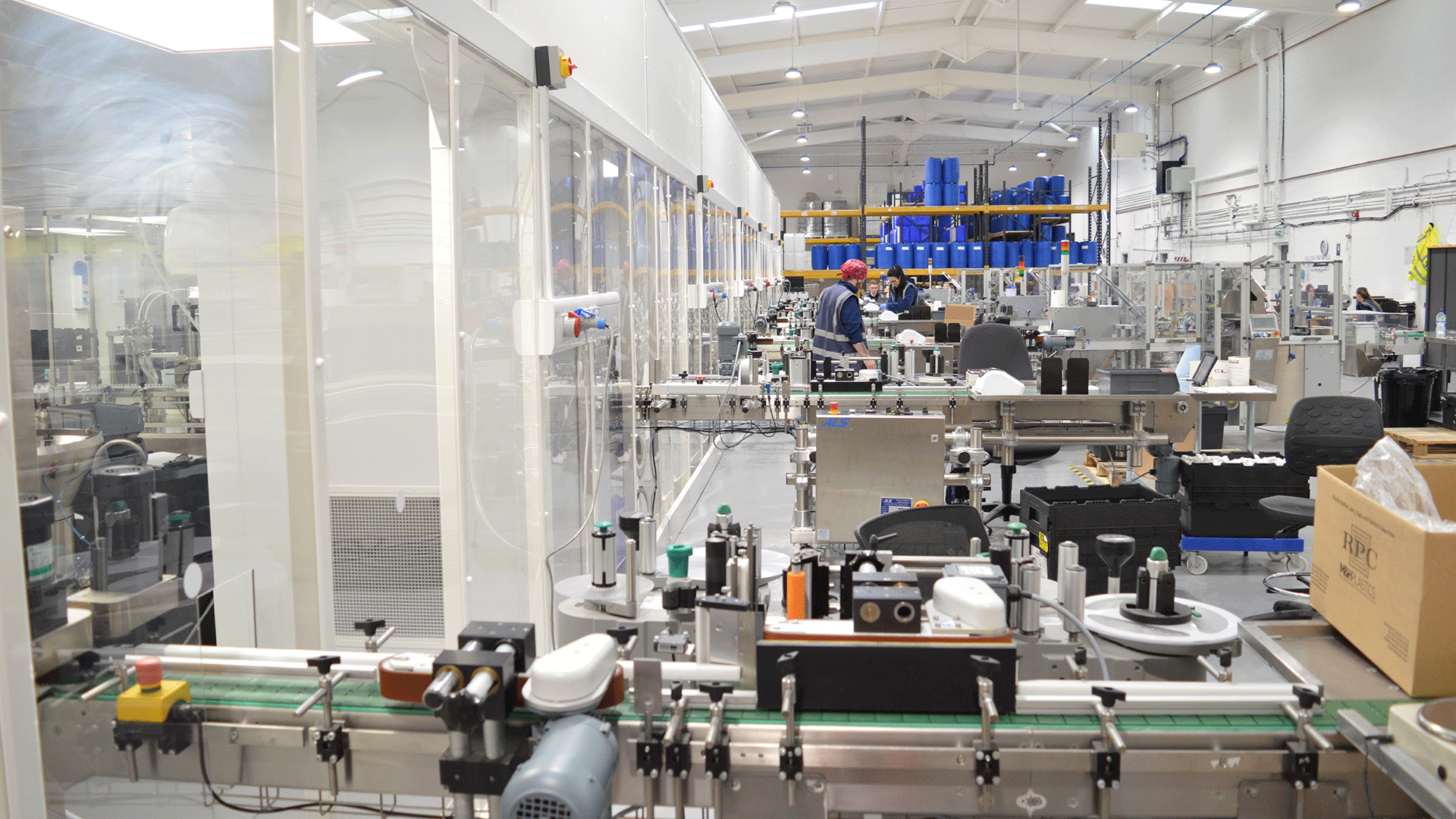

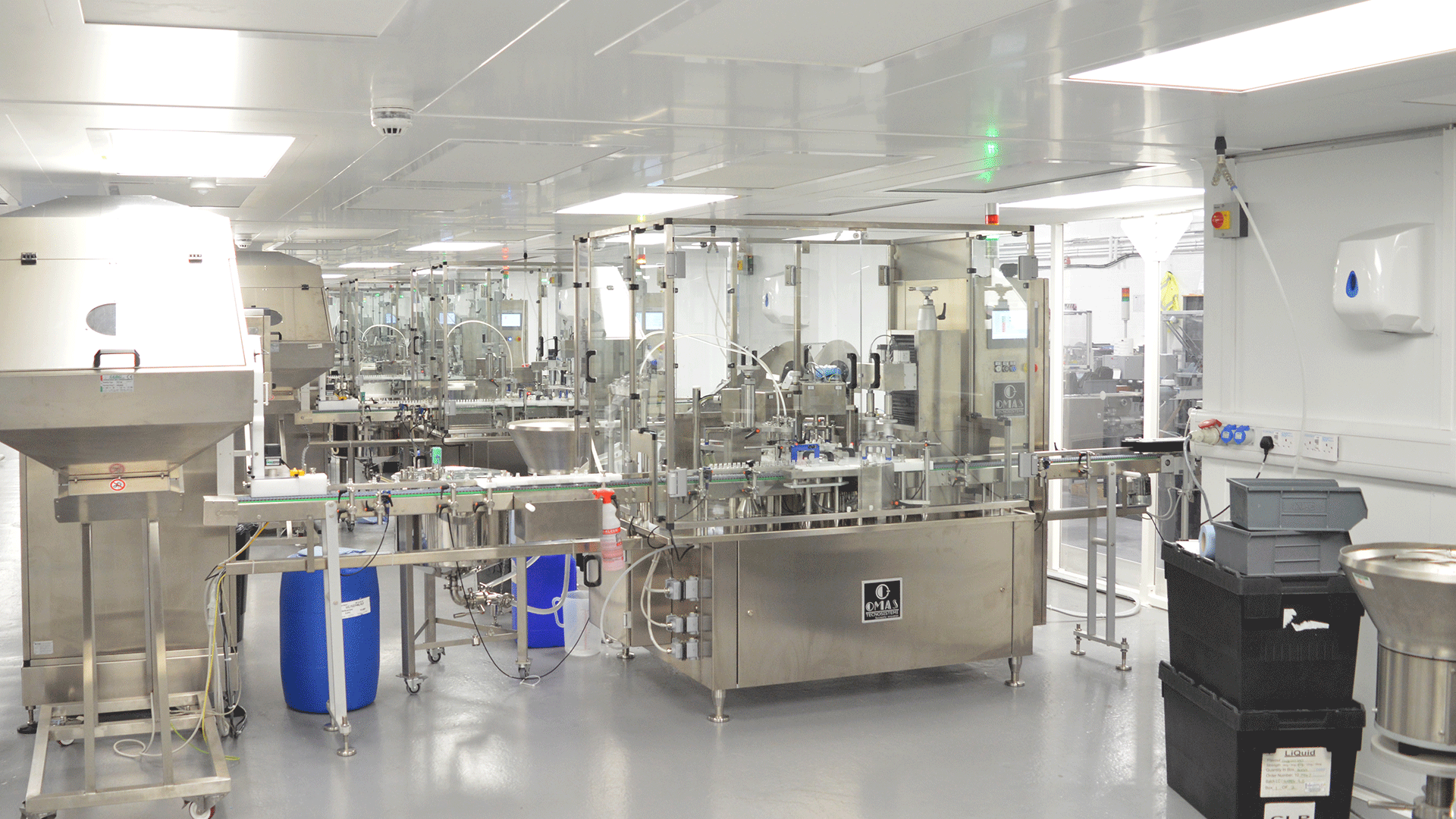

The cleanroom is constructed using a hybrid monobloc and hardwall envelope solution, balancing structural integration, fire protection and process visibility requirements. To support the mass production schedule of up to 8 million bottles a month, five interlocked rapid roll doors and a bespoke cleanroom machine interface to accommodate brand new and bespoke production machinery facilitate the efficient movement of materials along the production line.

How did the client benefit?

C2C’s ECO control system allows configurable control over the fan filter units which can be set to follow shift patterns. As well as controlling ancillaries, the ECO system actively monitors differential pressure, particulate contamination levels and temperature and humidity; alarming if the readings vary outside of a user defined threshold. All data is logged on a cloud-based server and is available for remote download and interrogation.

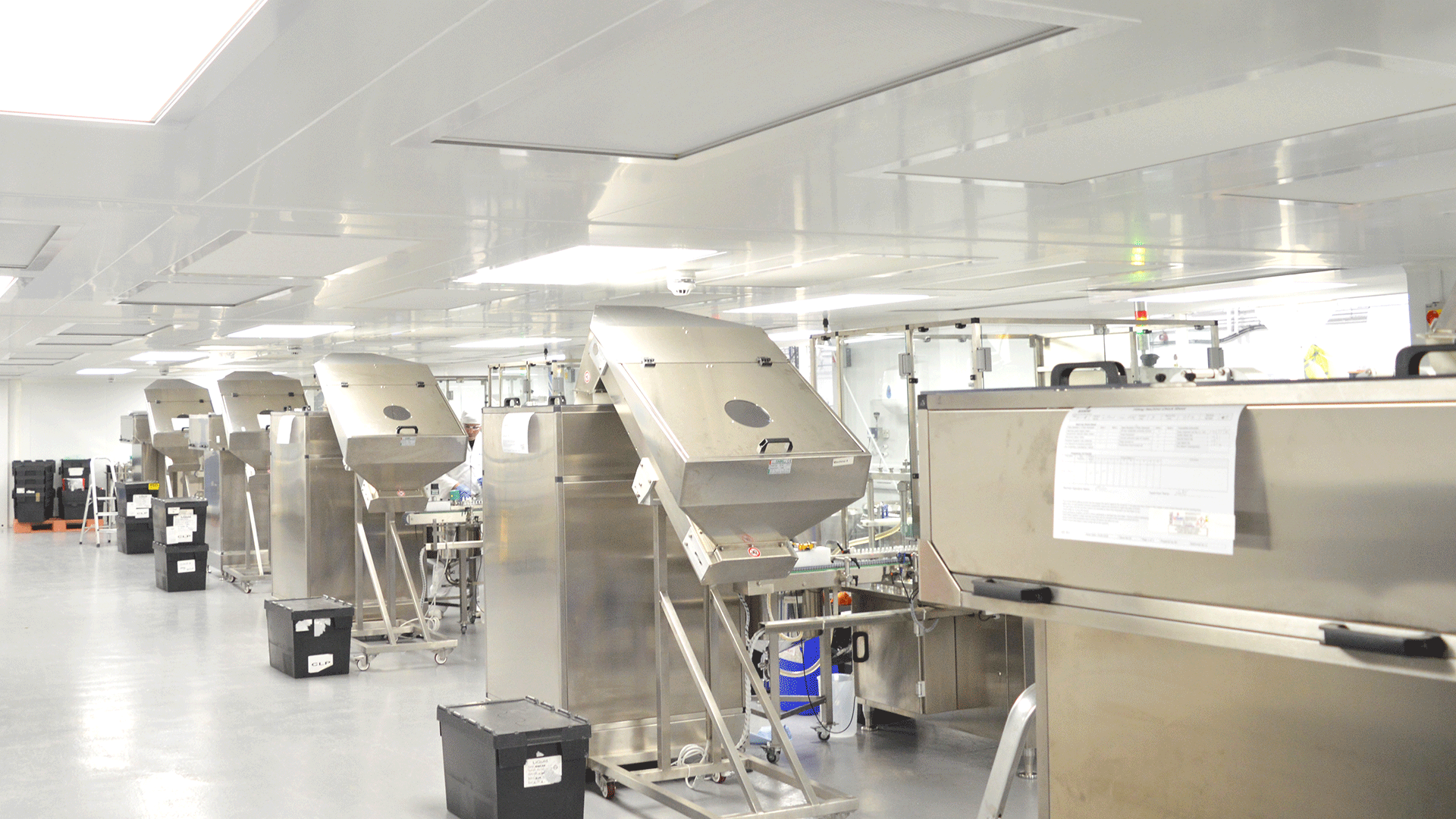

MAC 10® LEDC fan filter units provide advanced energy efficiency for the supply air, with a high efficiency particulate air (HEPA) filter (99.99% efficient @ 0.3 micron) and is a scalable unit which can easily be configured into future upgrades. The ECO control system provides live monitoring on the condition of the HEPA filters, monitoring efficiency to ensure efficient operation.

To support potential future upgrades to a cleaner ISO 14644-1:2015 grade, the fully-flush and sealed cleanroom ceiling is pre-apertured to accommodate additional fan filter units without significant disruption. The ceiling also houses flat panel LED lighting controlled by passive infrared (PIR) sensors and integrated with emergency lighting, providing enhanced energy efficiency and health and safety compliance.

How could we help the customer?

As well as comfort cooling in the main areas, Blend and Bottle required a warm room to manage the viscosity of the e-liquid prior to bottling, improving flow and production line efficiency. The warm room features heating up to 50°C ± 2°C and has been constructed with UltraTech Precision panels with integrated air return, to minimise heat loss. The warm room is controlled by its own proprietary control system allowing control and monitoring, as well as important health and safety features, such as an automatic shut off for the heater bank should airflow be reduced.

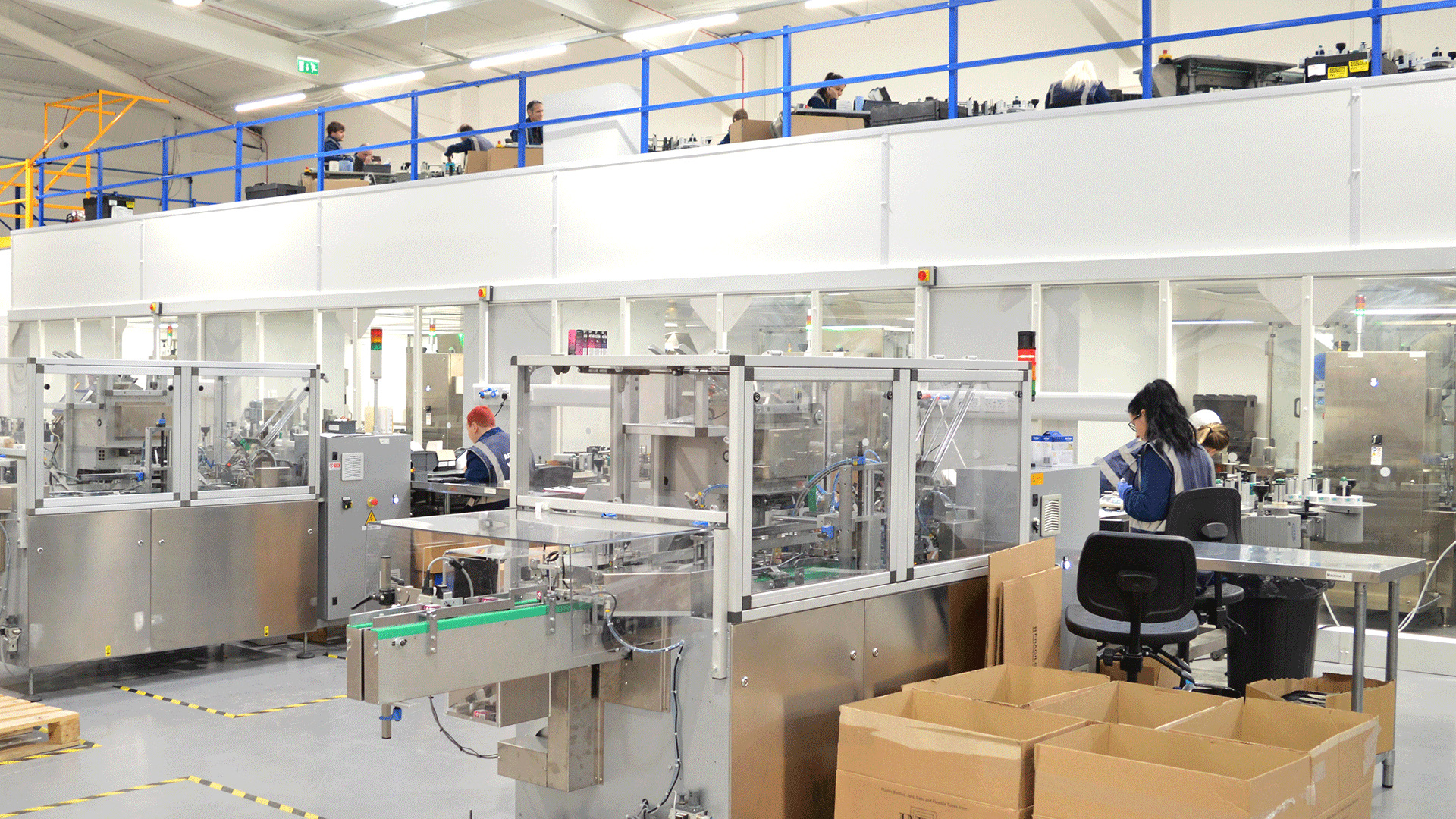

In the main cleanroom area, air return is provided through internal columns which means that clean and temperature conditioned air is recycled avoiding unnecessary over-processing. As the cleanroom has been installed under a mezzanine and visually integrated with a fascia, roofside access is limited, so integrated room-side replaceable (RSR) pre-filters have been used so planned maintenance can be conducted with ease.

This cleanroom facility balances health and safety, process demands and energy efficient cleanliness, which will help Blend and Bottle retain their lead in a growing and competitive industry.

The new facility installed at Blend & Bottle is testament to the relationship developed between the end user and Connect 2 Cleanrooms. To ensure both current and future production requirements can be accommodated within the new facility, a level of design flexibility was provided to allow for future ISO Class upgrade. Through collaborative design definition, the space utilisation underneath the mezzanine was maximised and provided a seamless integration to the existing facility.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE