The Cleanroom Design and Build Process

The cleanroom design and build process involves several critical steps to ensure the controlled environment meets the necessary cleanliness standards for specific applications, such as pharmaceuticals, electronics, and biotechnology. Here’s a breakdown of what the process looks like with Angstrom Technology.

Introduction and Discovery

Conceptual Design

Detailed Design

Specification Development

Delivery and Construction

Furniture Fit-Out

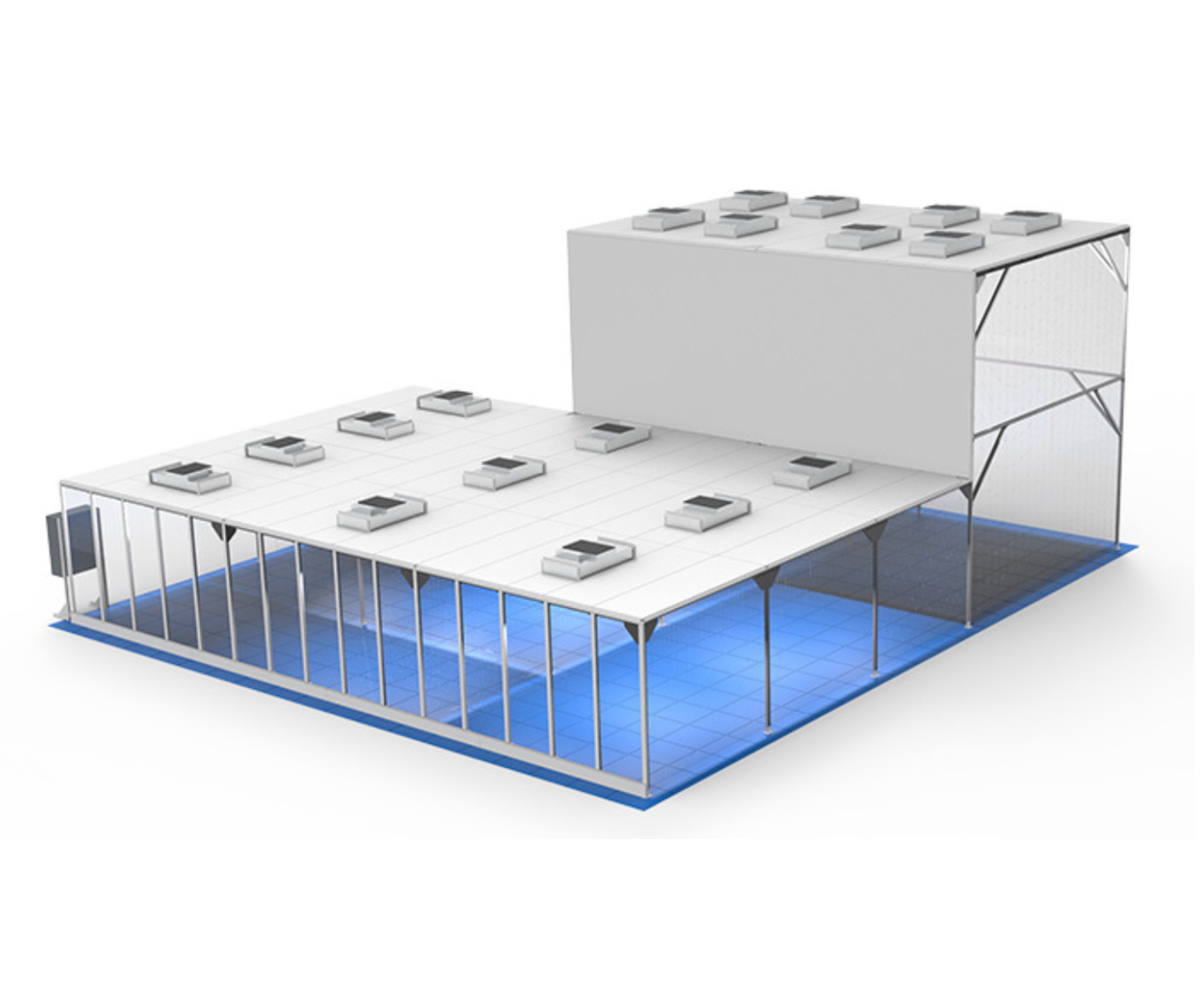

Cleanroom Design

Our experienced mechanical, electrical & architectural design teams can support your project with all aspects of the design and specification requirements of a project, with experience and knowledge of traditional and specialist cleanroom panel systems. We can assist from project conception to validation, with feasibility studies, capex / budget costs, design for tender process or as part of a design and build award.

Project Management

Angstrom Technology operates with in-house project management and architectural design teams familiar with a multitude of controlled environments of varying degrees of size and scale. This level of expertise allows us to transform your cleanroom aspirations into tangible, realistic solutions.

Mechanical, Electrical & Plumbing

Angstrom Technology have a large team of highly skilled technicians, specialising in construction, electrical and mechanical services. This means we have the ability to offer a full cleanroom installation package, from constructing the walls to installing the electrical systems.

Architectual fit-out

Angstrom Technology is a total architectural solution provider, with over 40 years of expert knowledge in the cleanroom industry. Working with our dedicated team, we’ll get to know your challenges, requirements and objectives and work together to provide you with the highest quality solution.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE