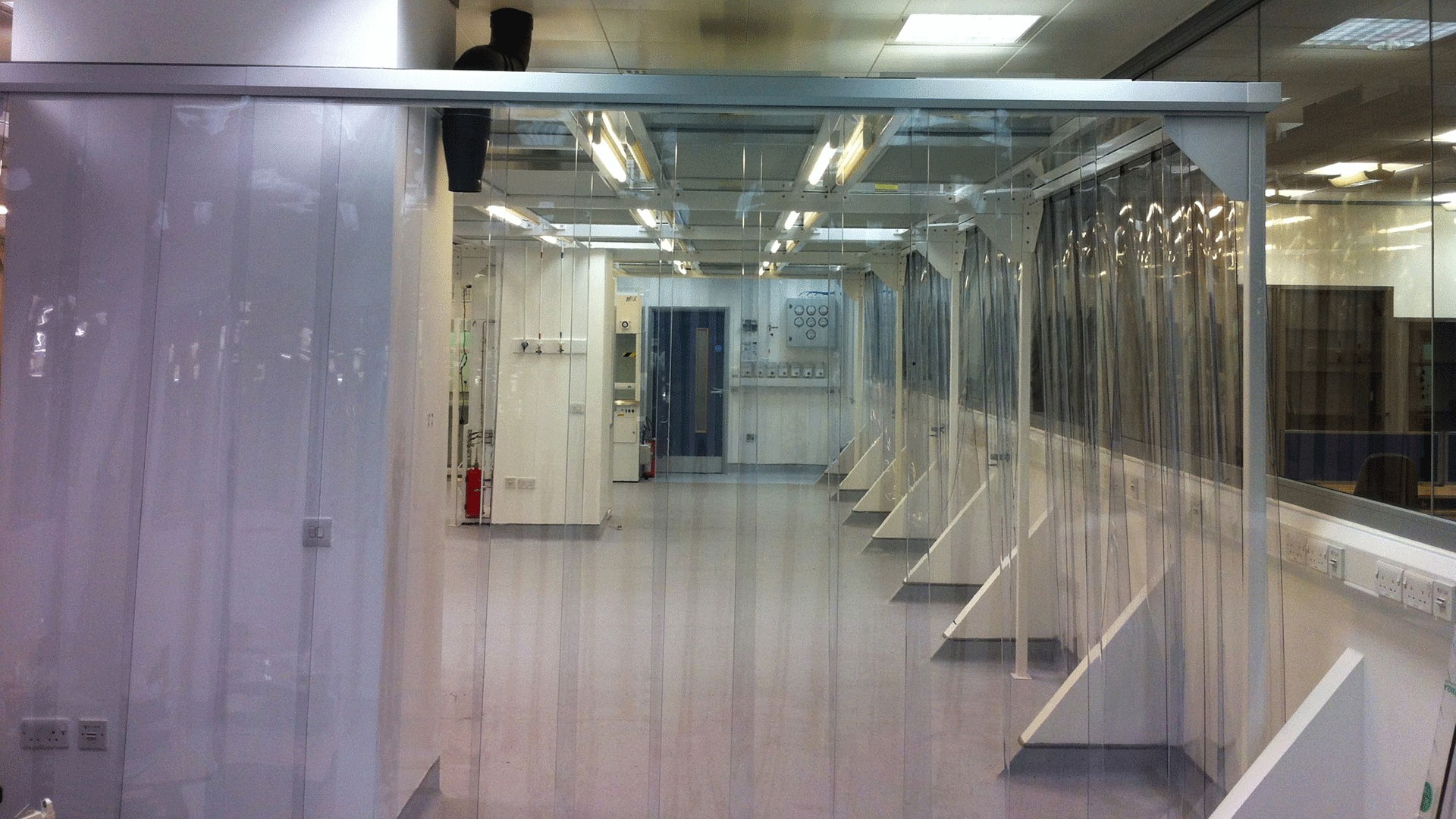

ISO Class 7 Cleanroom for UV Sensitive Nanotechnology R&D

Our client needed an ISO 14644-1 Class 7 cleanroom that maximised their working area within an existing laboratory space, at a university research centre.

Key facts

ISO class 7

Custom-built 21.3m² cleanroom

Relocated and extended in just 4 days

UV lighting and panels to block a certain spectrum of UV light

What did the client need?

Our client needed an ISO 14644-1 Class 7 cleanroom that maximised their working area within an existing laboratory space, at a university research centre.

Nanoco develop applications incorporating semiconductor nanoparticles, known in the industry as ‘quantum dots’.

They have expanded from a university spin-out to a global company, partnering major R&D and blue-chip industrial organisations, from the UK to the Far-East.

Nanoco simulate their client’s production environment, to allow accurate prototype development for semiconductor device applications. A clean-air environment is key to this, so back in 2009 Nanoco invested in a Connect 2 Cleanrooms modular cleanroom.

How did the client benefit?

A dual lighting option gives the client full control to switch between light spectrums.

The modular construction of the cleanroom facilities meant that when Nanoco needed to extend their space in February 2012, we were able to provide an efficient value proposition.

The cleanroom was relocated, extended and re-commissioned in the space of just 4 days; simultaneously bringing the cleanroom facilities up to date and retaining the value of their initial investment.

How did we help the client?

We designed the cleanroom to maximise the working area and house extraction equipment.

We also incorporated UV lighting and yellow softwall panels to block a certain spectrum of UV light.

The extension grew the original cleanroom from 47.7m² to 104m². This more than doubled the capacity of the classified ISO 14644-1 Class 6 area. Additional remote variable speed controllers were installed to give economic and efficient zone control for a total of 7 zones.

It was a logical decision to go with Connect 2 Cleanrooms for the relocation and extension of our cleanroom facilities as were happy with the way our existing facilities worked. The installation went smoothly as their engineers worked around other contractors on site and we found them very accommodating. The cleanroom meets all our expectations.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE