Cleanroom & Laboratory Suite for Diagnostic Device R&D

Acting as Principal Contractor, C2C collaborated with Engie, the onsite Business Energy & Services contractors, to deliver a purpose-built facility of 10 fully-fitted laboratory zones, including 2 cleanrooms.

Key facts

Cleanroom & laboratory suite

For diagnostics device R&D

10 fully-fitted laboratory zones

Including 2 cleanrooms

Principal contractor

Construction was undertaken during the COVID-19 pandemic

CFD study & 3D point cloud survey

To plot airflow throughout the building

The client

Phoenix DX, formerly LIG Biowise, has developed a point of care and high throughput diagnostics device that tests for a range of pathogens and delivers results in under 30 minutes. The device development has been accelerated to market as it can detect COVID-19 and common flu within 14-30 minutes and is being shortlisted for the Bionow Digital Awards 2021.

Certain processes, such as reagent preparation and laser routing are incredibly susceptible to contamination so Phoenix DX required new laboratory facilities including controlled environments at their facility on Salford Quays in Manchester.

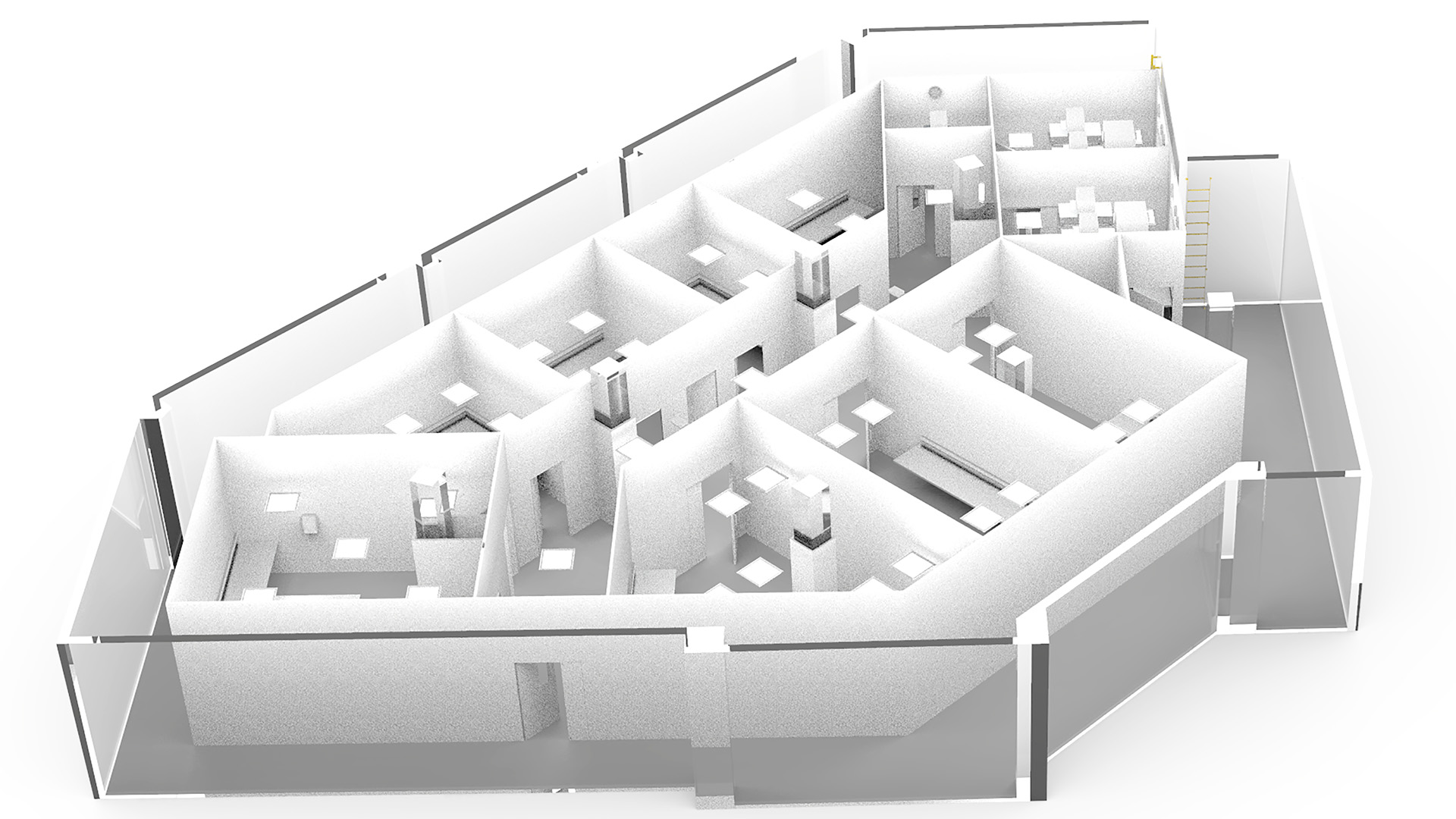

The Victoria is a redeveloped character building in MediaCity UK, one of the premier business locations in the North West. The art-deco style building gave Phoenix DX a unique diamond shaped floorplan in which to house the new facility.

The project

Acting as Principal Contractor, C2C collaborated with Engie, the onsite Business Energy & Services contractors, to deliver a purpose-built facility of 10 fully-fitted laboratory zones, including 2 ISO cleanrooms:

- Microbiology lab

- Post-amplification lab

- Pre-amplification lab

- Tissue culture lab 1

- Tissue culture lab 2

- ISO 7 prep and lyophilization

- ISO 7 microfluidic cartridge laser welding

- 4-Axis CNC micromachining

- 3D printing lab and laser micro matching lab

- Prototype Integration and testing lab

The two cleanrooms provide a primary classification of ISO 14644-1:2015 Class 7, as built, to protect the microfluidic cartridge laser welding and reagent preparation and lyophilisation processes. A further four service zones, includes a classified change area.

Using a 3D scan survey, our technical design team created a bespoke layout to maximise the laboratory footprint and verify the accuracy of the design. In addition to delivering ISO-compliant performance with a process-led design, the fresh and modern design complements the prestigious building in which it is housed.

Integrated cleanroom services

As an integrated cleanroom service provider, we provided a full furniture fit-out service, coordinated with the cleanroom installation to reduce overall project lead times and benefitting Phoenix DX with the opportunity to use a single point of supply. Sealwise laboratory benching was used to create antimicrobial and durable workstations.

On completing the cleanroom installation, our specialist team completed a full validation covering airflows, room pressures and particle counts from representative sample locations as defined within ISO14644-1:2015. An interim report was issued immediately and the full report to meet the needs of regulatory bodies was issued in just 2 days.

Phoenix DX received excellent service from C2C. Whole service transparency and project management was really very good. With a complete project like ours we sometimes needed a lot of information and C2C were able to deliver what we needed very quickly.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE