Cleanroom Design & Build Process

Over the past 40 years, we have become a trusted partner to clients globally, delivering thousands of turnkey and modular cleanroom design and build projects. Our multidisciplinary team designs, delivers and commissions complete cleanroom systems, undertaking full project management and ongoing maintenance along the way.

Our expertise means that we can support you throughout the lifecycle of your cleanroom environment, ensuring you achieve and surpass your objectives.

In this blog, we’ll explain the cleanroom design and build process from start to finish, highlighting what you can expect on your cleanroom journey with Angstrom Technology.

Introduction and Discovery

At the very first stage, we’ll get to know you and the project, understanding the specific requirements of the cleanroom. This will include the level of cleanliness required (ISO class or GMP grade), location and intended processes that will be conducted within the finished cleanroom.

Where required, we can produce accurate, non-invasive 2D live AutoCAD files of your existing facility, gathering onsite dimensions and images, using innovative laser measuring technology and recording equipment. Data collected during the survey can be used as an industry-standard digital record for future space planning. As part of this process, we understand that most existing facilities are within live critical environments, therefore only our most experienced specialist team, who are extremely familiar with GMP and critical environment procedures, produce these surveys.

Conceptual Design

This is the first phase of the cleanroom design process, where layouts and other models, such as renders, are used. It is a draft consisting of ideas and concepts about what space the room should offer and allows you to evaluate the proposed specification. We will then work collaboratively with you to achieve the right combination of operational parameters, that will deliver results.

Detailed Design

In the detailed design phase, the ideas and concepts evolve into concrete plans, required specifications and exact definitions of dimensions, materials and components, defined in a User Requirement Specification (URS).

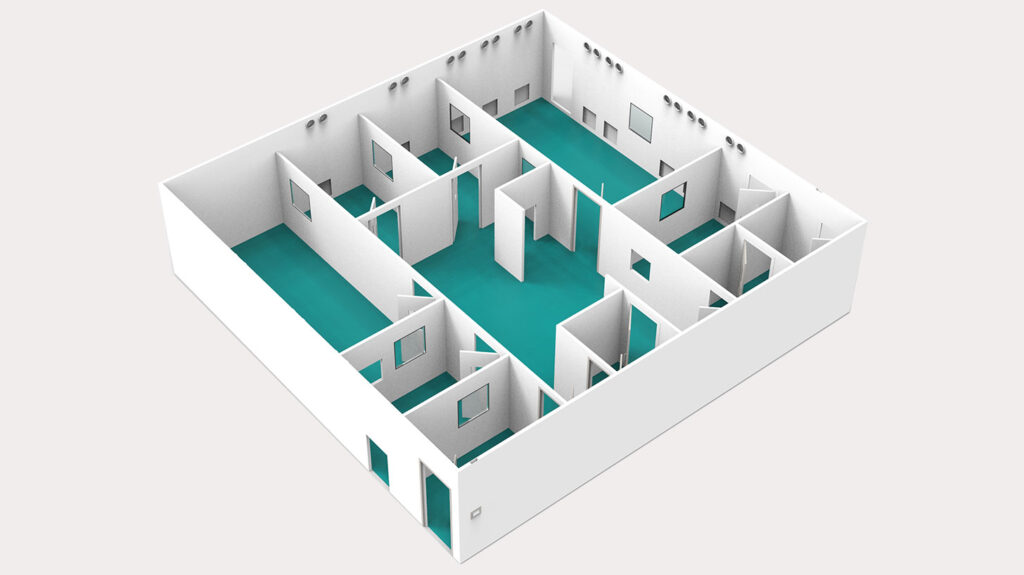

The URS defines processes, equipment, operations, capacities and environmental criteria for the cleanroom design. Our Design team will review the flow of people and products through the facility to assess the optimum layout for compliance, efficient operation and minimisation of cross-contamination. Once the URS has been approved, the functional design specification (FDS) will be developed.

Specification Development

At this stage, the physical components will be selected, choosing the most appropriate materials for walls, floors, ceilings and fixtures that meet the desired cleanroom standards.

Our team of Bid Engineers will work with our supply chain partners to build a proposal that covers an agreed scope and presentation. Our Design team will get to work producing a comprehensive suite of building information models (BIM) for you to review and approve.

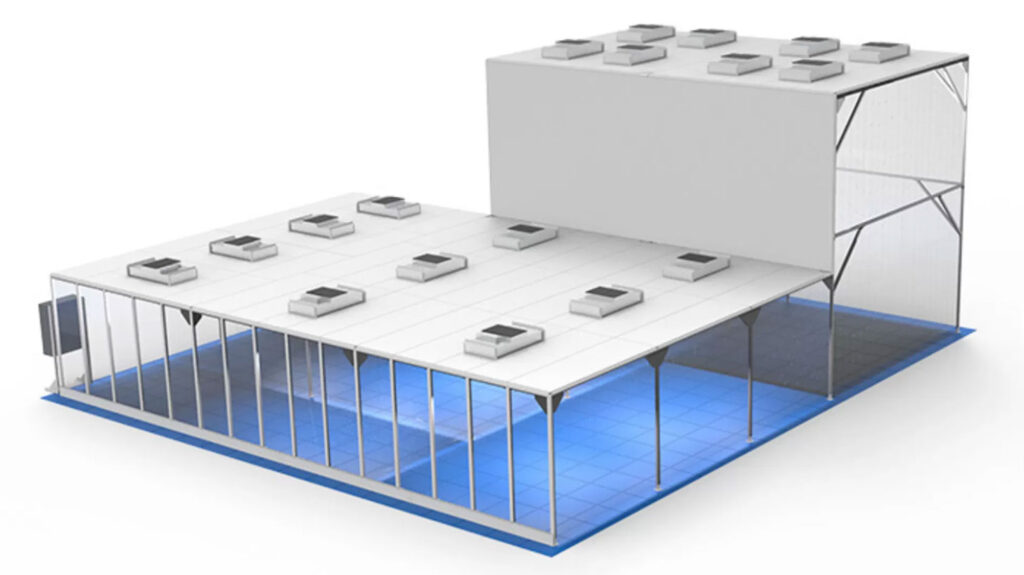

The building information model uses modern surveying equipment, allowing us to 3D scan the current environment of your facilities and carry out clash detection to verify that the proposed cleanroom design operates in line with the planned process and its surrounding environment. 2D and 3D models allow you to visualise the project, including virtual reality walk-through tours to test the layout and workflow.

Delivery & Construction

This is when on-site work begins and our team, supported by supply-chain partners and managed by a dedicated Project Manager, will see the build through every stage, from foundation to validation.

This construction process involves the frame build, then the cleanroom walls, floor and ceiling panels according to the design specifications. We’ll then install the HVAC, electrical, plumbing and any specialised systems that are required.

Facility Handover

Our qualified Validation Engineers will validate and commission your new facility, providing a full validation report and all the necessary paperwork before we hand over. We can also build a validation service agreement to cover your validation requirements for a single year or multiple years to come, so you can rest assured your facility will continue to operate within the specified operational parameters.

Furniture Fit-Out

As soon as you’re ready, our Cleanroomshop team will pull together the best options for your cleanroom furniture, equipment and consumables. For internal fit-outs, we provide high-quality furniture in a range of materials to suit your process and budget, all whilst meeting the required ISO and GMP standards.

START A PROJECT WITH US

Our team are here to help you every step of the way, throughout the cleanroom design & build process. If you’re ready to discuss your next project with us, contact us today.

REQUEST A QUOTE